Hot Dip Galvanizing Equipment

Lighting Poles Galvanizing Equipment Hot dip galvanizing equipment

Lighting Poles Galvanizing Equipment Hot dip galvanizing equipment

The Main Process of Hot Dip Galvanizing Acid mist in Pre-treatment area acid pickling tank could be absorbed by mist spray absorber. Dust in middle treatment area could be absorbed by smoke absorb device. Waste water treated by treatment equipment should align with processing specification, and reusing into galvanizing line. This design ensures the whole production line will not smell acid mist and smoke, neat and clean factory environment and three waste treatment can reach environmental protection standard, and gives fine economic and social benefits for your company.

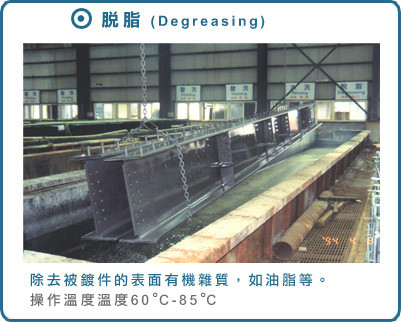

Degreasing: During processing, storage and transportation procedure, iron and steel parts usually will use oil in basic components of mineral or animal or plant oil, with several organic additives or inorganic substance. These are the principal oil contaminants from steel surface which must be removed thoroughly by degreasing .Traditional degreasing requires a temperature of 70℃ using a site hot-water boiler to heat degreasing tank.

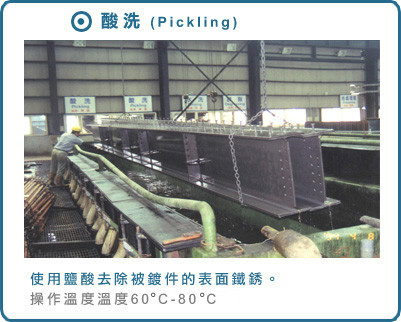

Acid pickling: Acid picking processing use hydrochloric acid pickling and add descale additives at the same time. Hydrochloric acid could keep in ordinary tank after the addition of descale additives, acid mist are efficiently retrained and no acid mist absorption devices are demanded. It also can protect that workpiece substrate will not treat with hydrochloric acid avoiding the formation of rough surface of parts after acid pickling which will increase consumption and cost.

Rinsing: Acid pickling part should be immersed into rinsing tank and after washed ,we could flush the surface with high pressure water ,in order to avoiding the Fe-ions into plating tank. The used flushed water could be recycled and supplemented into rinsing tank.

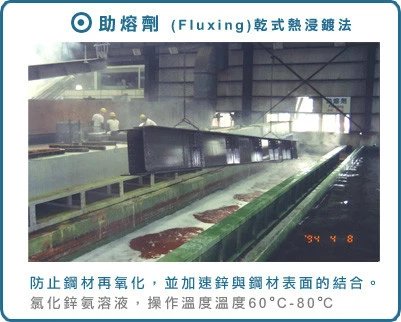

Flux: A special processing high efficient heat ex-changer can be installed in the smoke tube. The heat exchanger will collect the smoke and waste heat with a temperature of 466~518℃in the tube, and heat the water in heat exchanger reach to more than 95℃. By the control of thermal storage tank (outer-carrying insulation), pipe, fluorine plastics heat ex-changer, heat pump and electric control cabinet, the liquid in flux tank’s temperature will reach to 65℃ by heat communication. Due to the fine processing temperature, cleanliness of galvanizing liquid, rapidness of the workpiece pre-soak treatment, strong adhesion, fast surface drying, when the workpiece enter galvanized boiler it will not have mass zinc explosion after pass the flux tank.

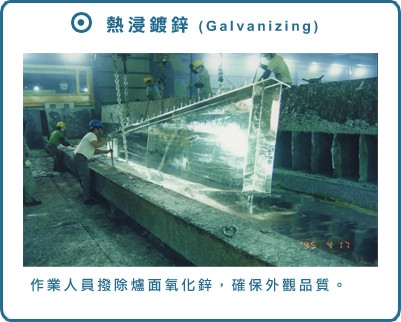

Galvanizing: Galvanizing quality determination depends on the mass of zinc ingot, components of zinc bath, temperature of zinc bath, immersion time and the speed of plating parts taken from galvanizing furnace, etc. According to characteristics of your galvanized parts, we can accurately control galvanizing solution temperature by using high-speed velocity fire galvanizing furnace as a key device, temperature could elevate rapidly and adapt to the temperature variation from large capacity. In addition, as a galvanizing device and service supporting party, we could provide further technological services for your galvanizing line in the future to ensure that the device could bring for customer the greatest achievement and helping customer to control galvanizing quality.

Cooling, Passivating: Cooling and passivating tank should be made by concrete. Meanwhile, pipeline should also be pre-laid in the tank for facilitating circulation and further processing. Chrome-free passivator imported from India is used for further processing. More than 100 hours salt-spray test after passivating could prevent the formation of white rust to realize bright galvanizing surface and to eliminate environment pollution and the damage to the health of operating workers from hexavalent chromium.

Our company mainly business scope is as follows:

1) The design, manufacture, installation, commissioning and training of the hot dip galvanizing lines, redesign and improve of the old galvanizing plants.

1. Jobbing galvanizing line for construction parts: such as steel tower , tube tower parts, high rails and lighting poles , etc.

2. Galvanizing lines for steel tubes:suitable for 1/2"-8" steel tube.

3. Galvanizing lines for small parts:suitable for bolts, nuts and other small parts.

2) The related chemical preprocessing of products and alloy

Our main products are : chemical pretreatment tanks, galvanizing furnace, zinc kettle, utilisation of fuel gas from the fuel furnace, drying pit.